Distillery Process Information:

Types of Distilled Liquors/Spirits

Distillery Calculations

Distillery Industry Links

Background

Just as in a sugar factory there are a number of measures of operational efficiency in a distillery. In the sugar industry ratios like extraction, boiling house recovery, and overall recovery are well defined and universally understood. Sadly in the alcohol industry things are a little more disorderly. To help bring a little order the following is offered

Theory

There are four commonly used measures of yield

- Fermentation yield

- Fermentation efficiency

- Alcohol recovery

- Overall Conversion Efficiency

Fermentation yield

Fermentation yield is measured in litres of absolute alcohol in beer per ton of sugars in molasses, and is calculated by the formula below

Yf = Vb · ab / (Mm · fsm)

where

Fermentation efficiency

Fermentation efficiency is an expression of how much alcohol was actually produced in beer relative to the amount that could be theoretically produced, and is given by

Ef = Yf · 0.794 / 0.5111 × (100/1000)

The factor 0.794 corresponds to the specific gravity of absolute alcohol and the factor 0.5111 is best explained as follows: If one kilogram of sugar was completely fermented (using theoretical 100% efficient yeast); 511.1 grams of alcohol and 1000 – 511.1 = 488.9 grams of carbon dioxide would result.

Alcohol recovery

Alcohol recovery is a measure of how much alcohol was finally produced relative to the amount that was in the beer. It shows the amount of losses in the evaporation and distillation sections combined. Alcohol recovery is calculated as follows

Ede = (aaVp + ssVf) / aaVb · 100

where

Overall Conversion Efficiency

Overall conversion efficiency is a measure of how much alcohol is finally produced relative to the amount that could be theoretically produced, and is given by

Eo = Ef · Ede · 100

Values of Yield

The following table gives values of yield that one would expect in a well run distillery

| Parameter | Value |

|---|---|

| Alcohol Recovery | 98.5% |

| Fermentation Yield | 573 |

| Fermentation Efficiency | 89% |

| Overall Conversion Efficiency | 87% |

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

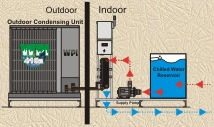

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |